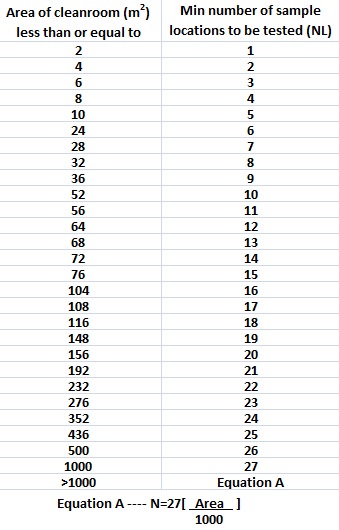

Key differences iso generally requires fewer sampling locations than fs 209e with iso number of sample locations is based on clean room area whereas with fs 209e it is based on class size of clean room and whether or not.

Clean room standards for pharmaceutical pdf.

Quality production laboratory materials facilities and equipment packaging and labeling.

Iso 8 class 100 000 0 005 0 041 1 8 5 48.

The most frequently used standard is the iso 14644.

A room which the concentration of airborne particles is controlled and.

A presentation of the revised 2015 cleanroom standard iso 14644 parts 1 and 2.

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area.

It takes an incredible amount of technology to achieve and maintain these objectives.

Class iso 146144 1 federal standard 209e average airflow velocity m s ft min air changes per hour ceiling coverage.

2 bs 5295 clean room standards bs 5295 class 1 also requires that the greatest particle present in any sample do not exceed 5μm.

Iso 6 class 1 000 0 127 0 203 25 40 150 240.

The presentation focuses on the key features for particle control and cleanroom classification.

If you are a manufacturer of non sterile medicinal products you should define your own clean room area standards using national and international standards.

The level of air cleanliness in the room must be regulated by standards.

Iso 5 class.

In the uk british standard 5295 is used to classify cleanrooms.

The hvac system for cleanrooms is a specialized field requiring thorough understanding of cleanliness guidelines airflow streams room pressurization temperature humidity and.

Iso 7 class 10 000 0 051 0 076 10 15 60 90.

Phen602 pharmaceutical facility design fall 2008.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

Usually manufacturers will define an airborne particulate concentration standard class such as iso 14644 1 iso 8 at rest outline gowning and a pressure cascade regime defining a.

In theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

3 iso 14644 1 clean room standards class 209e.

It is a document that establishes standard classes of air cleanliness in terms of airborne particulate levels in cleanrooms and clean zones.